Aluminum Extrusion in Manufacturing: Process, Profiles, and How to Choose

Aluminum extrusion is a foundational process in modern manufacturing. It transforms raw aluminum into high-precision profiles used across industries—from architecture and transportation to electronics and automation.

While our introductory article explains what aluminum extrusions are and why they matter, this article goes deeper: uncovering how the process works, what profile types exist, and how to choose the right extrusion for your project.

What is Aluminum Extrusion?

Aluminum extrusion is a manufacturing process where a heated aluminum billet is pushed through a die to create a continuous profile with a fixed cross-sectional shape. This is known as the aluminum extrusion process, and it typically involves:

- Billet heating

- Extrusion through a die

- Quenching and cooling

- Stretching and straightening

- Cutting to required lengths

- Optional surface treatments (e.g., anodizing, powder coating)

The result is a durable, versatile aluminum profile ready for fabrication, finishing, or assembly.

Why Aluminum Extrusion Is Widely Adopted

What makes extruded aluminum such a popular choice in industrial design and engineering?

Rather than repeat the technical benefits, we invite you to explore our detailed explanation here: 5 Key Advantages of Aluminum Extrusion

This guide focuses on helping you understand profile types, application scenarios, and how to choose the right extrusion for your needs.

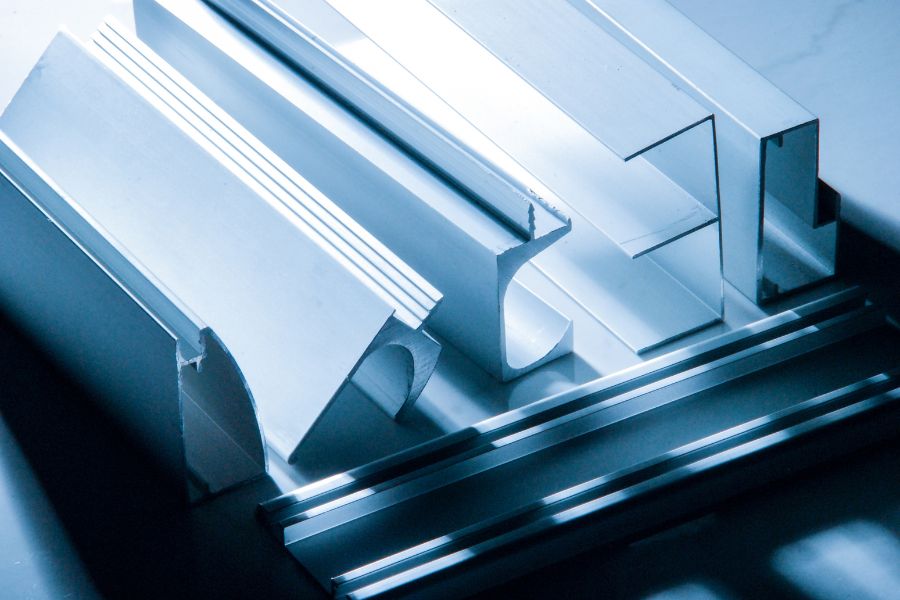

Types of Aluminum Extrusion Profiles

Aluminum extrusion profiles can be broadly categorized into:

- Solid profiles No internal cavities. Examples: angles, channels, flat bars.

- Hollow profiles Profiles with one or more voids. Examples: tubes, square boxes.

- Semi-hollow profiles Partially enclosed sections, such as tracks or C-shapes.

You can choose from standard aluminum profiles extrusion or work with a custom aluminum extrusion manufacturer to design geometry tailored to your application.

Common Applications of Extruded Aluminum

Extruded aluminum is used extensively across multiple sectors:

- Construction & Architecture Window frames, curtain walls, handrails

- Electronics Heat sinks, casings, LED housing

- Transportation EV battery trays, trailer panels, structural supports

- Automation & Machinery Modular frames, motion tracks, enclosures

- Renewable Energy Solar panel racking systems, wind turbine parts

In these applications, aluminum extrusion profiles are favored for their light weight, strength, corrosion resistance, and aesthetic adaptability.

How to Choose the Right Aluminum Profile

When selecting aluminum extrusions, consider the following key factors:

- Profile dimensions and tolerances Do they fit your product assembly requirements?

- Aluminum alloy type Choose 6063 for architectural uses, 6061 for structural performance.

- Finishing requirements Anodized aluminum finish, powder coating, or brushed surfaces.

- Machining or post-processing needs Will you require CNC aluminum machining, slotting, or tapping?

- Production volume and lead time Align your timeline with your aluminum extrusion supplier’s capabilities.

The right partner can help you balance performance, cost, and production speed—especially for custom shapes or high-precision applications.

Conclusion: Empower Your Design with the Right Aluminum Profile

Aluminum extrusion gives manufacturers the freedom to design smarter, lighter, and more efficient components. Its versatility and repeatability make it a go-to solution in every major industrial sector.

Have a design in mind or need help finding the right profile? Explore our aluminum extrusion services or contact us for a free consultation.

FAQ

Q1: What is aluminum extrusion and how does it work?

Aluminum extrusion is a process where aluminum alloy is forced through a die to create a specific shape. This method enables the production of complex, lightweight, and strong components used across many industries.

Q2: What are the main benefits of using aluminum extrusions?

Key benefits include design flexibility, corrosion resistance, high strength-to-weight ratio, thermal conductivity, and cost-effectiveness.

Q3: What types of aluminum extrusion profiles are available?

There are solid, hollow, and semi-hollow profiles, with options for custom designs to meet specific structural or aesthetic needs.

Q4: Which industries use aluminum extrusions the most?

Common sectors include construction, automotive, electronics, renewable energy, and industrial automation.

Q5: How do I choose the right aluminum profile for my application?

You should consider the end-use environment, structural requirements, profile dimensions, and any surface finishing or secondary machining needs